On Monday, I tried to use a thermal press to test creating a connection of melted Delrin. However, a side effect of that is that then there are big protrusions. This would mean that slide array would be full of knobs, not flush and much thicker than it could be if I had decided to use press fits.

I think that the thickness of the array is important. Not only would it save material, but also, since it is going to be installed on the inside of a packed cabinet, the less space it takes up, the more convenient it is.

Therefore I decided to use press fit.

I also tested my piece by taping it to a cabinet door to test how easy it is to jostle the toggle out of its correct state. The good news is that the dips for the dowels are actually deep enough that even a sharp closing or opening will not jostle the toggle out of a set state. However, the state can be accidentally changed through a sleeve catching on the dowels and changing the state of the toggle.

In order to reduce the chance that that happens, the dowels should be shortened so that they don't stick out as much.

nitpicking problems and my modifications to resolve them

1) deciding to do press fits means I need to decrease how much the pins stick out past the holes.

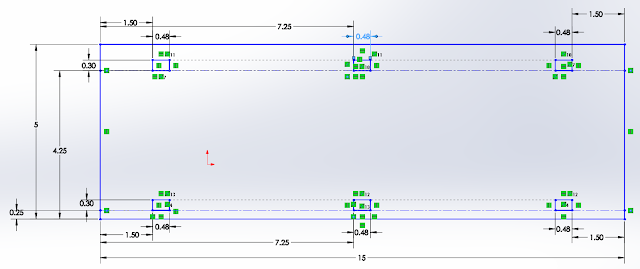

I measured that pretty much on average the pins stick out about 1mm out from the surface of the front and back. Finally, an instance where the 4th way to measure using a caliper, using the caliper head, the way that many people forget to use. Then, I decreased how much the pins stick out in my Solid works model by 1 mm.

1) spacer gives a little too much space.

using the caliper, I determined that there is a 6.5mm space for a 3.25mm thick toggle to sit in.

while I do want to leave some space

I changed the spacer distance from .65 cm to 0.40 cm or a decrease of 0.25cm

If this turns out to be too tight, then I can increase the spacer distance to .45 cnm

2) the connection between back front and spaces was pretty good initially, but it loosened up a bit. it wasn't so loose that I would feel concerned that it might fall apart accidentally, but I feel like it could be better

it is a pretty good press fit, but I feel like it could be better.

I am putting it 7.25cm from the left.

on the spacer, because the spacer width is 0.4 larger than it was initially, then

currently the solid works difference between the pin and the hole, or the total allowance (allowance on boths sides) is 0.48cm- 0.7635cm or 0.00375 cm or 0.0375 mm. after careful examination of the pin hole connection, I figure that I could probably increase the allowance between .3 mm - .4mm. increasing the current allowance gives something in between 0.3375 - 0.4375mm. neither those values doesn't divide very nicely by 2 very pretty, and so rather than having an allowance of that I think I will have an total allowance of 0.40mm

1.50cm = 15.00 mm. thus with a 0.40mm allowance, the pin(on the spacer) should be .4mm or 0.04cm bigger than the hole.

3) the spacer has a tendency to warp in the up down direction.

to fix that I am putting in a third connection point in between my two connection points that I had to connect the spacer with the front and back. in my original design, there are only two connection points for each spacer. in the new design there are three. This decreases the length given to the spacer to warp. this would make the whole structure more rigid.

4) Given that I was going to put in a third connection point on the spacer, I felt like I could get away with using an even thinner Delrin than a 1/8 in Delrin. However, after quite a lot of fishing around. I found that there wasn't enough of the thinner delrin sheets to make my thinner array dream a possibility, and it was unlikely that newly ordered delrin would arrive in time. Therefore, I stuck with the current thickness of material. Oh well, at least I know it's very rigid.

5) I am going to experiment with different length of dowels such that it is still easy to operate but still short enough such that it isn't too easy to bump toggles out of state.

consequently I ended up changing the designs for the front, back and spacers.

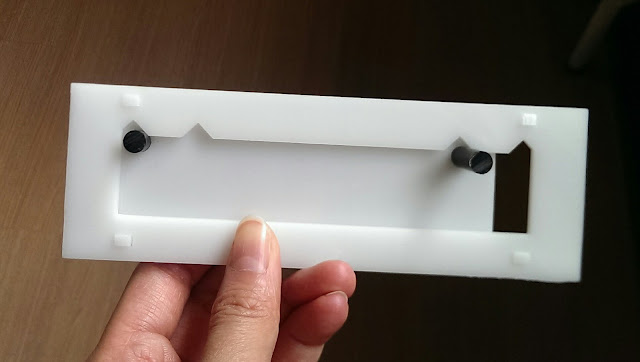

after designing the new pieces, I printed them out and assembled them. they look very nice.

on Monday I stayed from 1:30 - 5:30.

The new version is shown above. It is thinner.

The new version is shown above. It is thinner.

The new version is on top. It is thinner, but it still moves pretty well. (And it also happens to have toggle upside down)

IN this picture I have tried using different paints and markers to color the back to indicate whether a toy is available or not. In the top I used a oil-based paint. on the bottom I used permanent marker. I think the bottom one looks nicer. However, with both versions, the back of the toggle is scraping off some of the painted color. I think maybe I will cover up the colored parts with clear tape to protect the paint from being scraped off, just for aesthetics.

I also tried to heat stake the dowels, but it didn't work very well because it added significant thicknesses to the toggle, and because I am valuing the thickness of the array, I opted for a tight press fit rather than heat staking all of the dowels.