So, having come up with a good sample toggle that I was satisfied with, I set out on creating the whole array.

I copied the pieces that needed to be changed (front and back and spacers) into their own files.

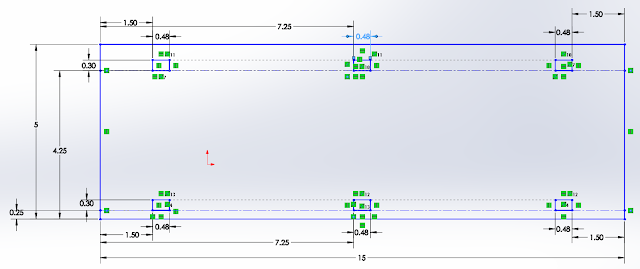

For the front and back pieces, I wanted to the same pattern on a 2x6 grid and so what I did was that I copied and pasted 6 on one side and then I mirrored the patterns on to the other side.

When you mirror it is helpful to create an infinite line for construction.

What I learned is that when you select elements with a selection box, if the entire element is not int the selection box then it is not selected, and when you go to mirror or copy it, it will not be mirrored or pasted. curiously enough this applies to dimensions as well, so if you don't select dimensions, the dimensions won't be copied over and the dimensions can be accidentally changed. So as a reminder. make sure every element that you want copied, including dimensions are all selected in your copy-paste or mirror stage. I understand there is a more elegant way of copying a pattern on a grid, but I didn't figure it out and so instead I just used copy paste. and it seemed to work decently well enough, one just has to be careful.

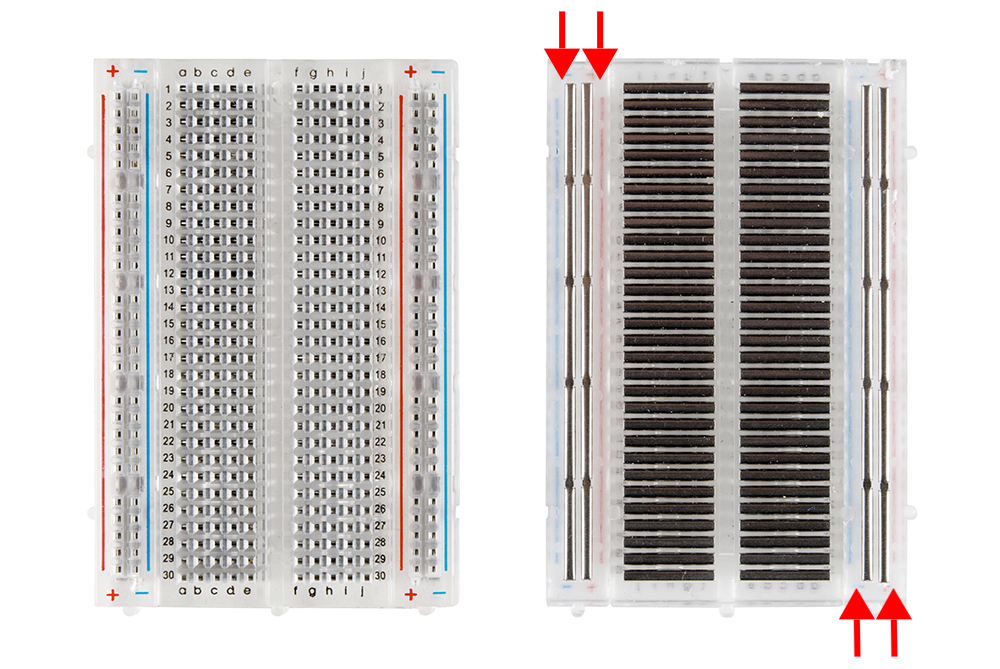

This is the back:

This is the front piece with all of the windows

as you can see, I didn't copy past very carefully and had to redefine the distance from the edge to the center joint for each window pane.

this is the spacer. its just been mirrored from the last version.

although the toggles haven't changed, I've included a picture anyways, just for reference.

Then I got the laser cutter to cut the pieces out.

Unfortunately many of my pieces turned out very poorly. the Delrin warped significantly under the heat and the lines were double cut so that some weren't even cut out.

Actually, the back board and all of my 12 toggle pieces were all salvageable and I didn't need to re cut them. The holes in the back board, due to being double cut were too big in the x dimension due to being double cut in the x dimensions, but I could fall back on the accurately cut x direction to hold the joints tightly. As for the toggles, even thought the holes weren't cut all the way through, I was able to use the drip press and a piece of meta to press out the holes. The resulting holes weren't very pretty(they looked like they had been shot), but they remained mostly serviceable. apart from a couple of holes where the double cutting had made the holes so large that the weren't even

I ran out of 1/8 in Delrin, and had to use something that was slightly thinner. It wasn't labeled with its thickness but if I were to guess from the imperial system. I would guess 3/32.

it looked to be a different material as well, because it was much whiter, and didn't have as shiny a flat surface. When it was being cut with the laser, the cut etch was a lot shinier and glossier than the normal delrin, didn't bend as much fr om the heat and only took one pass through to be completely cut. all in all it was a much nicer material for the laser printer. I also got the impression that it was easier to chip than the other material.

However, it as thinner than what I had planned, and while the 1/8th delrin cut in my original dimensions may not have broken, the thinner piece that I actually ended up using did chip. I'm also not sure if it was because the material was different formulation of delrin. when I hammered it into place, i really ought to have started with the center ones and then moved out to the joints towards the edge. instead what happened was I started with the joints on the edge and after tightly fitting some joints that made fitting the remaining joints more difficult and resulted in some unnecessary breaks and chips. I could have also done something like what you are supposed to do on car wheel screws, where you never commit to just one nut all the way but incrementally tighten all joints. I also dropped my array several times on the hard ground, which is also not something that I would recommend doing to a acetal piece. I guess if I was really serious about it I could have gotten a clamp, because I know what level of clutzy-ness I am capable of.

Everything had to and fitted very tightly and precisely. This annoyed me, but also presented sum unforeseen benefits. the annoying part was that I had a smaller acceptable margin of error for laser cut errors like double cutting or excess heating. It also meant that assembly was tricky, as everything had to light up and match up correctly. In the end, I created something that wouldn't be very easy to pry apart, which is a positive feature.

I failed to take any pictures, so I guess you'll have to believe me when I say that each of the 1/8th pieces of delrin was significantly warped and curved before final assembly. However, after I assembled, everything was held very tightly and rigidly and all of the warping disappeared as the friction in the joints and the rigidity of the pieces served to make the entire pieces almost as straight as the ideal shape that I had in my Solidworks construction

This image was taken before I tapped together all of the joints. It shows that rather than using red and green markers, I used colored sticky notes, which are less likely to rub off than the markers.

The sticky notes were cut just wide enough so that no matter which state the toggles were the back of the dowel rods would never travel past the edge of the sticky note and so it could never lift off the sticky note from the edge.

This image shows before the front was pounded into the spacers and connected with everything else.

The small hammer was super useful and I feel like there should be another small hammer around just in case the small one gets broken or lots because the small hammer is a wonder.

This is the completed array once it's been hammered together.

The dowels don't stick out too much and the overall thickness isn't that thick either, and in this image you can see that the top plate is much thinner than the bottom plate.

If I were to continue on this path, I would consider increasing the margins of the piece, so that there was more material between the outside joints and the edge of the whole array for the front and consequently the back. I think that would cut down on the chipping.

If I were serious about producing this I would seriously consider building and constructing the whole thing out of something that isn't delrin, acetal. As my professor pointed out, Delrin, or acetal, is very expensive.

Here is a picture of my toggle array from the back.

I also helped my partner with her part of the project. I suggested that she change her program so that rather than making the lights go off when the light level gets to be a certain medium light level, a tricky thing to master, that the lights should go off based on a change in state from dark to light.

I helped her understand what types were and what a boolean type is and how to initialize and use boolean. The islight variable should be set to false anytime the lightness reading is less than a certain constant and the islight variable should be set to true anytime the lightness reading is greater than that certain constant. one should have a global value to remember one's past light state, and each time through the program loop, if the current reading is light but the previous reading was dark, then this signals a change in light state representing an opening closet, and then the light show should begin. I also helped her debug her script. She had tried to assign strings to a variable of type integer, and she had tried matching a string to a variable rather than another string (the difference being that strings are surrounded by quotation marks- light is a variable, "light" is a string constant that you can compare against. )

Later on, when her wires weren't working, I helped her understand that her wires were backwards. she had the idea that since ground was where electricity flowed into and electrons flowed from the negative terminal, that the ground should be attached to the positive line. However, as we know from physics, thanks to Benjamin Franklin, current(electricity) actually flows from positive terminal to negative terminal even though electrons flow in the opposite direction, from negative to positive.

I introduced my partner to wire strippers and alligator clips. We used wire strippers, because there wasn't enough exposed metal to comfortably connect two wires together. She had some trouble sliding the plastic casing off of the metal wire after cutting the plastic casing. She tried bending back and forth, which one shouldn't do because it risks the structural integrity of the metal wire(as in you can break the wire, like you do with a paperclip bent back and forth too many times). Then she gripped the wire strippers too tightly as she tried to slide the plastic casing off the interior metal wire. the extra friction made it difficult to slip off the plastic casing, and it also cut part of the metal wire inside.

I also helped her understand that the code that she downloaded from the internet was not for the led strip that she was using, as the led strip that she was using only had one input, but the code assumed three inputs for the three colors, red, green and blue. She had two pins in the arduino connected to the led strip, one that was connected to the input line, and the second that was connected to one of the ground lines. This did not work.

I also pointed out that she needed to have capacitors, otherwise she was creating a short circuit that may or may not have blown out some bulbs.

The led strip apparently requires 12volt battery, however I also learned that when you connect batteries in series(pos to neg) then you increase the voltage(measured in Volts(V)), but when you connect batteris in parallel(pos to pos, then neg to neg) then you increase the capacity(measured in Amperage hours (Ah))

This article is really informative